Orezone Intercepts Further High-Grade Mineralization Below Life of Mine Pits Including 1.59 g/t Gold Over 48.00m and 1.09 g/t Gold Over 45.00m

VANCOUVER, British Columbia, Aug. 19, 2025 (GLOBE NEWSWIRE) -- Orezone Gold Corporation (TSX: ORE | ASX: ORE | OTCQX: ORZCF) (the “Company” or “Orezone”) is pleased to provide additional drill results from its ongoing multi-year exploration campaign at its flagship Bomboré Gold Mine. The latest results are from the North and P8P9 zones, targeting the down plunge continuity of higher-grade sub-zones beneath the current life of mine pits.

Selected Drill Highlights1:

- 1.59g/t Au over 48.00m, including 4.86g/t Au over 9.00m (BBD1358)

- 1.09g/t Au over 45.00m, including 2.56g/t Au over 8.00m (BBD1370), within a broader mineralized intercept of 0.64g/t Au over 157.00m2

- 1.97g/t Au over 16.10m, including 2.74g/t Au over 10.10m (BPC7217)

- 2.01g/t Au over 14.00m (BPC7216)

- 2.67g/t Au over 7.40m (BBD1367)

- 1.63g/t Au over 11.00m (BPC7216)

- 1.48g/t Au over 8.75m (BBD1369)

- 1.82g/t Au over 6.40m (BPC7210)

- 1.16g/t Au over 9.00m (BBD1369)

- 1.47g/t Au over 6.50m (BBD1368)

- 1.01g/t Au over 9.00m (BPC7217)

Patrick Downey, President and CEO stated, “These latest drill results confirm the down plunge continuity of multiple higher-grade sub-zones, with mineralized traces extending beneath the current resource pits, and remaining open at depth. The targeted drilling at the North and P8P9 zones further underscores the near-term potential at Bomboré to selectively pull higher-grade reserve pits to depth across the greater 14km long reserve defined trend. Of particular significance is the very broad sub-zone of mineralization at depth in P8P9. This zone does not appear at surface and is the broadest zone of continuous mineralization that has been intercepted at Bomboré, demonstrating significant exploration potential.

The results of this concentrated drilling serve to complement the ongoing wider spaced step-out drill program, which is focused on identifying new higher-grade centers of mineralization both at depth and near-surface along strike.

In H1-2025, approximately 30,000m of exploration drilling was completed at Bomboré. We are extremely pleased with the results and success of the program to date, which includes 1) extending North Zone footwall mineralization up to 200m below the current reserve pits along an 800m strike length (including 2.55g/t Au over 23.00m and 1.14g/t Au over 29.50m), 2) extending mineralization of the P17S high-grade sub-zone a further 300m down plunge (7.40g/t Au over 6.70m) and 3) identifying multiple broad near surface strike extensions (including 2.22g/t Au over 14.00m, 1.12g/t Au over 10.00m and 0.92g/t Au over 14.35m).3

Drilling will continue in H2-2025 on multiple fronts in support of the Company’s long-term goal of increasing Bomboré’s current stated global resource from 5 million ounces4 to a targeted 7 to 10 million ounces longer term.5 This is truly an exciting prospect with the ongoing hard rock expansions positioned to increase Bomboré’s overall production to 220,000-250,000 ounces per annum.6”

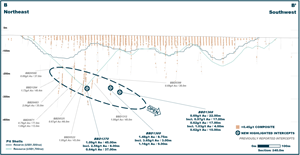

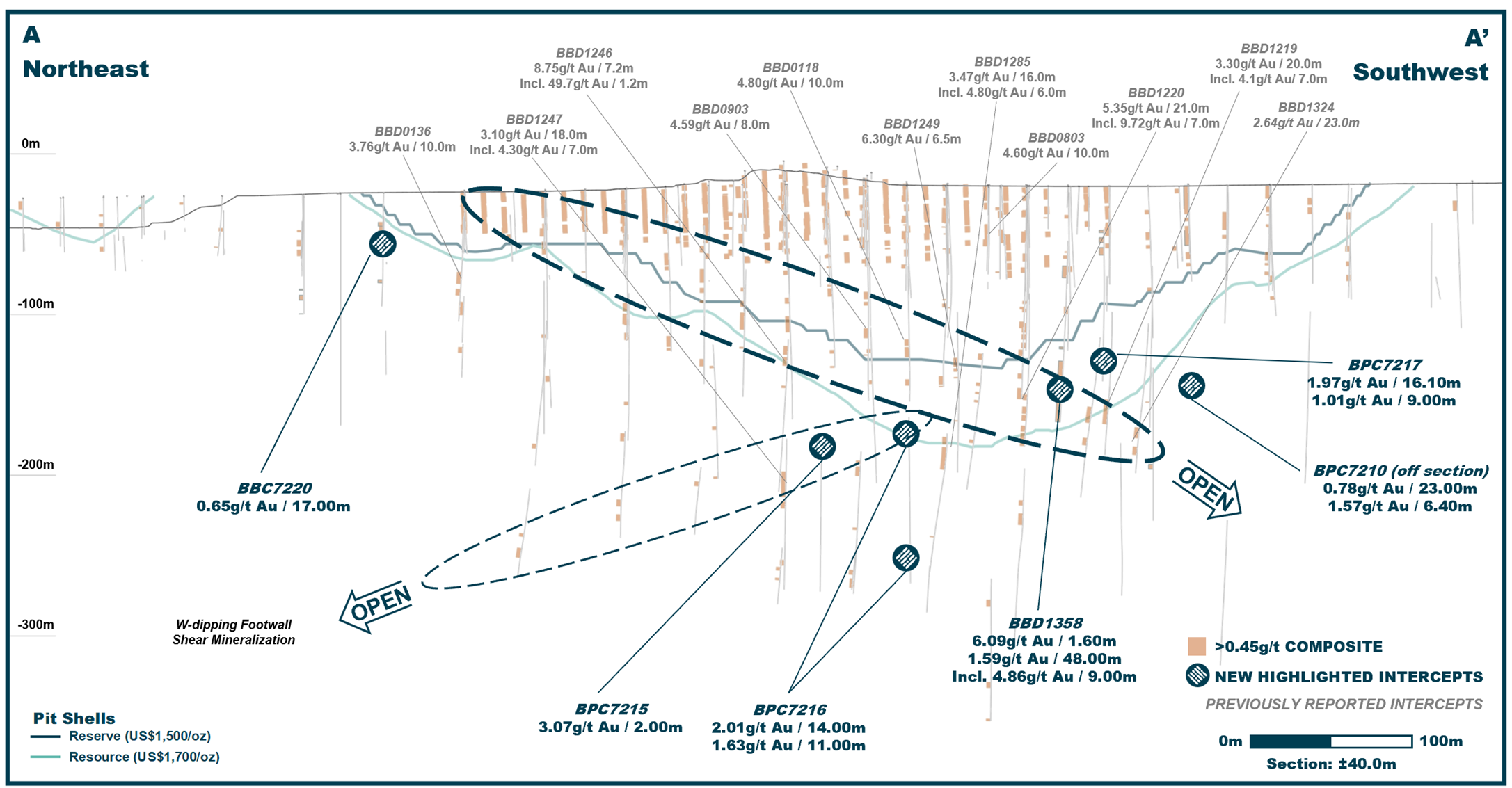

North & North Hill Zone

The ongoing drilling program continues to define and expand mineralized trends along the 3km strike length of the North Zone. Mineralization in the shear-hosted “Footwall Zone” is associated with rheological and chemical differences between siltstones and shales and the volcaniclastic footwall sediments. Gold grades are correlated with quartz veinlets with disseminated pyrite and arsenopyrite as accessory minerals. Ore shoots are developed where north-northeast trending steep-dipping shears intersect the northeast trending and easterly dipping footwall shear. Fold hinge and stretching lineation measurements confirm the moderate north to north-northeast plunging mineralization.

The North Hill Zone, which sits east of the Footwall Zone, continues to deliver promising grades and widths with higher grades corresponding to increased extensional quartz veining. These veins occur between two steep-dipping north-northeast trending mineralized deformation zones suggesting on-going deformation has resulted in sites of dilation orthogonal to the steeper shears.

The recent drilling was successful in confirming 1) the down plunge continuity of the higher-grade North Hill sub-zone beneath the life of mine reserve pit (including intercepts of 1.59g/t Au over 48.00m and 1.97g/t Au over 16.10m), and 2) further delineating higher-grade mineralization within the west dipping footwall shear (2.01g/t Au over 14.00m). Both of these higher-grade trends remain open to depth, and will be the focus of future follow-up drilling.

North Hill Zone: selected high-grade sub-zone intercepts (previously reported7):

- 5.35g/t Au over 21.00m (BBD1220)

- 3.14 g/t Au over 18.00m (BBD1285)

- 3.30g/t Au over 20.00m (BBD1219)

- 2.55 g/t Au over 23.00m (BBD1324)

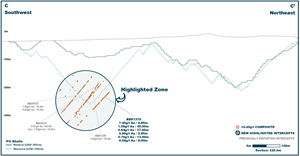

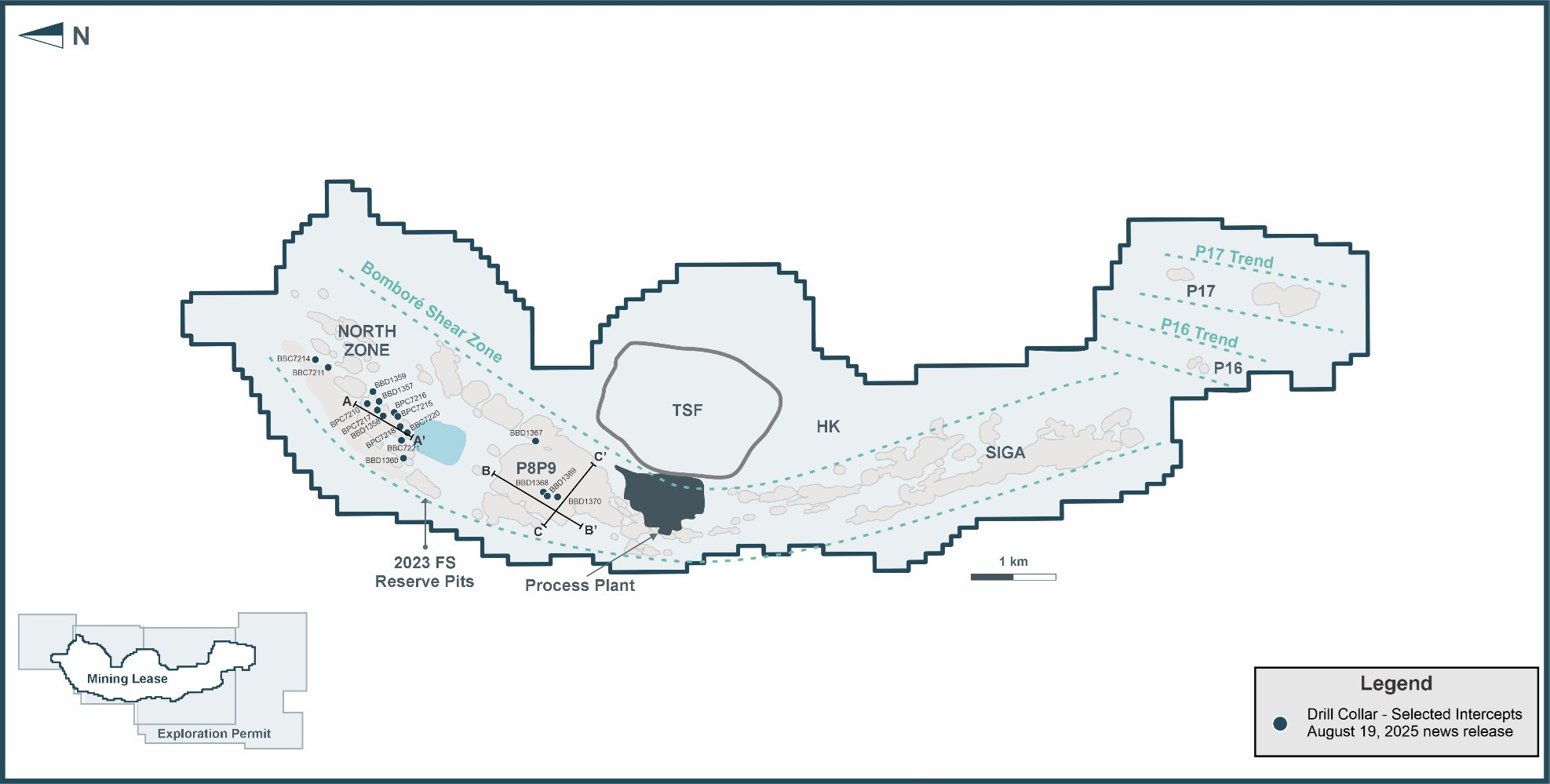

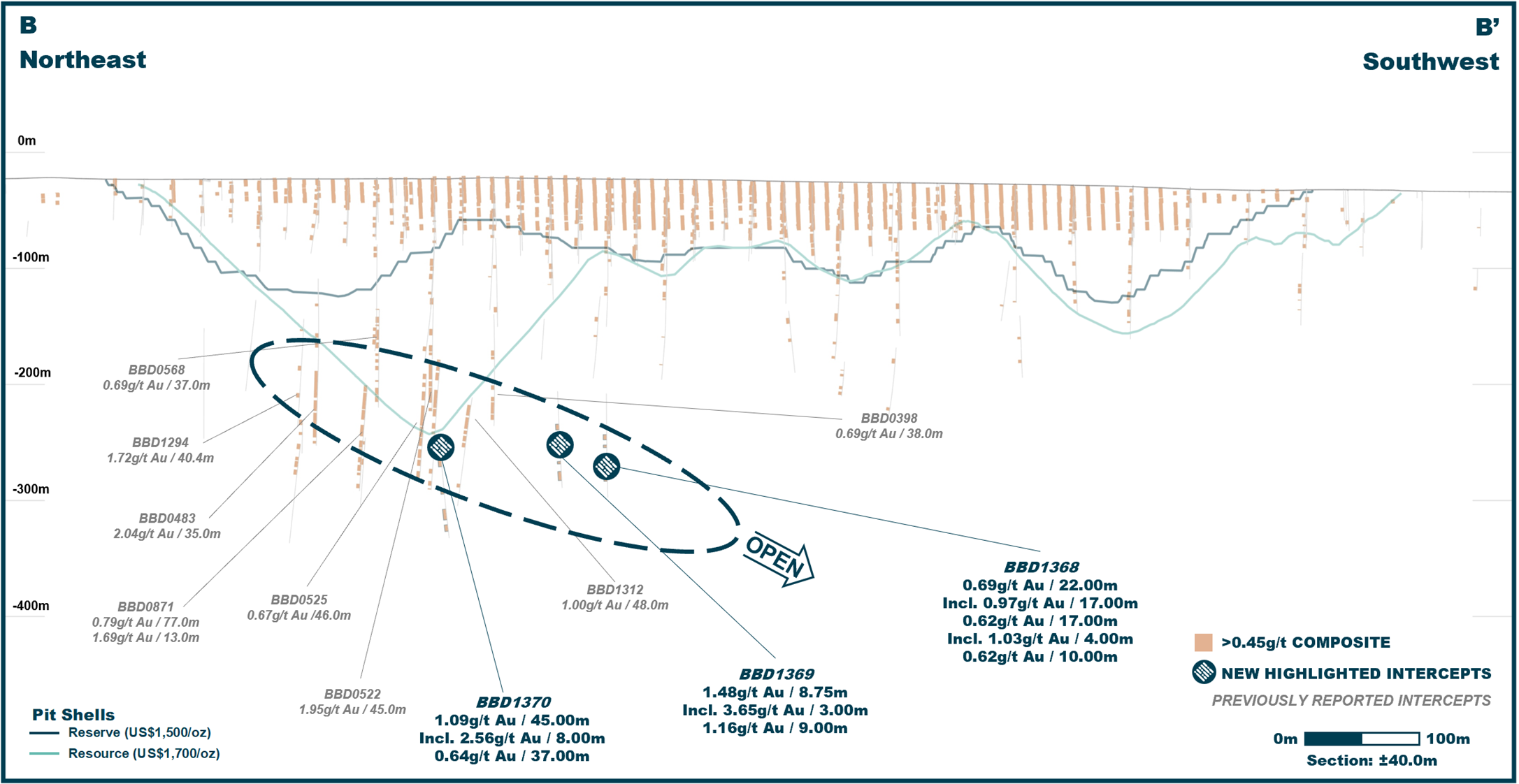

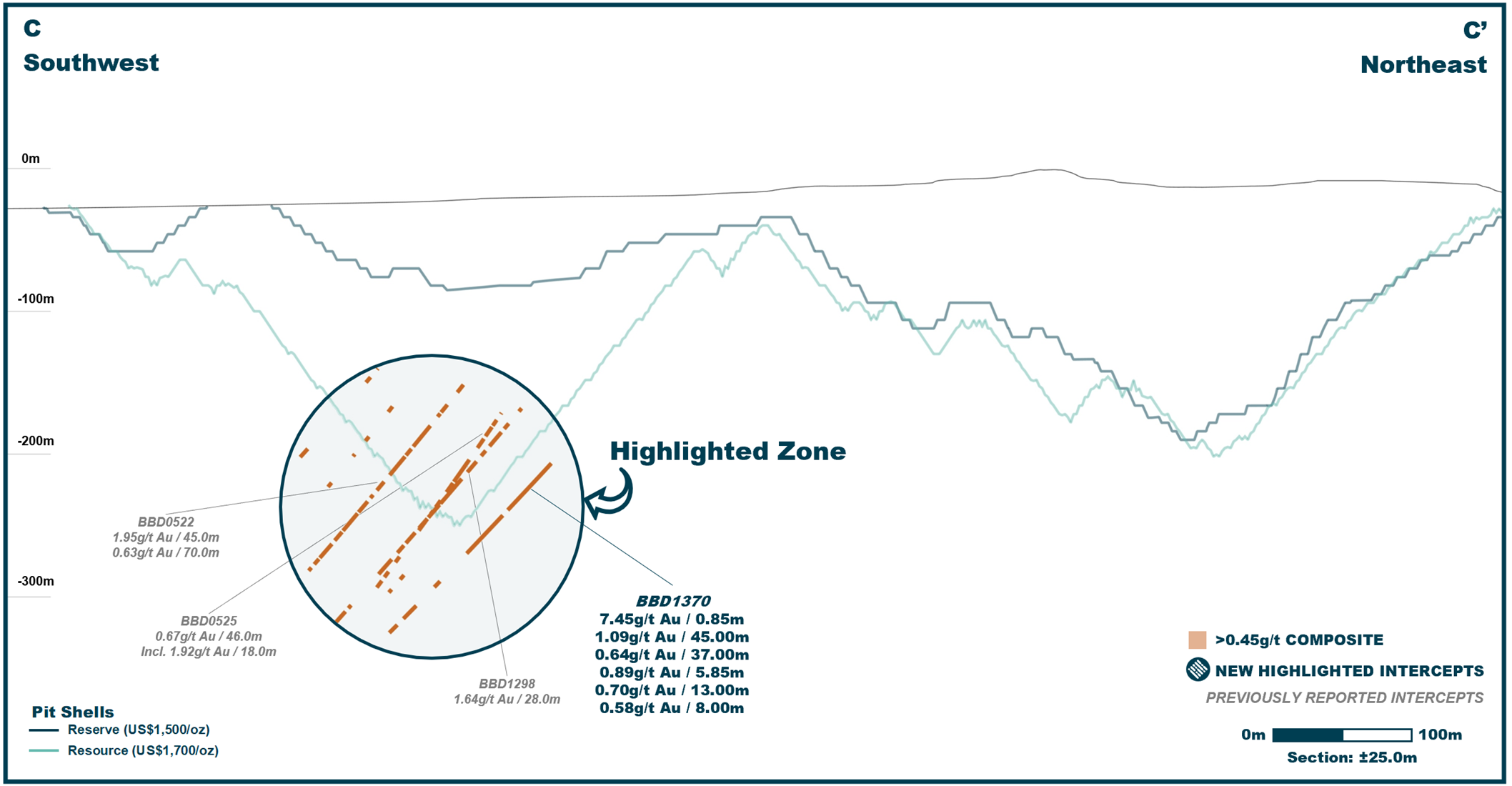

P8P9 Zone

The north-northeast trending P8P9 Zone is separated from the North Zone by an ephemeral drainage channel. Mineralization is defined over a 1.6km strike length with a width of 1.4km at its widest point. Discrete north-northeast higher-grade lenses occur within wide low-grade pyrite rich zones dipping steeply to the east. Similar to North Hill, zones of flatter lying extensional quartz veining are also present.

Mineralization intersected in holes BBD1368, BBD1369 and BBD1370 demonstrate the potential for wide zones of mineralization with no significant expression near surface. Mineralization is hosted within a granodiorite unit with abundant disseminated pyrite with above background gold levels throughout. Of note is hole BBD1370 which returned 1.09g/t Au over 45.00m, within one of the widest mineralized intercepts on the property to date of 0.64g/t Au over 157.00m8. Overall, this step-out drilling at P8P9 was successful in extending this zone of higher-grade mineralization by a further 100m down plunge.

P8P9 Zone: selected high-grade sub-zone intercepts (previously reported9):

- 2.04g/t Au over 35.00m (BBD0483)

- 1.95g/t Au over 45.00m (BBD0522)

- 1.72g/t Au over 40.40m (BBD1294)

- 1.06g/t Au over 44.00m (BBD1312)

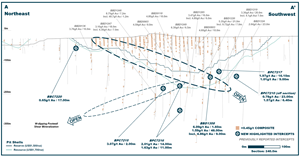

Figure 1 – Bomboré Plan Map Highlighting Selected Intercepts

Figure 2 – North Hill Zone Composite Long Section Highlighting Selected Intercepts (Looking Southeast)

Figure 3 – P8P9 Zone Composite Long Section Highlighting Selected Intercepts (Looking Southeast)

Figure 4 – P8P9 Zone Composite Cross Section Highlighting Selected Zone (Looking Northwest)

Table 1 – Drill Results Table

| Hole | Zone | Easting | Northing | Elv. | Dip | Azi. |

EOH (m) |

From (m) |

To (m) |

Length* (m) |

Grade (g/t Au) |

Type |

| BBC7203 | P11 | 728012 | 1349498 | 285 | -50 | 268 | 150 | 74.00 | 75.00 | 1.00 | 7.70 | OX |

| and | 134.00 | 135.00 | 1.00 | 1.58 | HR | |||||||

| BBC7204 | P11 | 727922 | 1349498 | 291 | -50 | 268 | 101 | 0.00 | 7.00 | 7.00 | 0.54 | OX |

| and | 79.00 | 82.00 | 3.00 | 1.07 | HR | |||||||

| and | 93.00 | 95.00 | 2.00 | 2.22 | HR | |||||||

| BBC7205 | P11 | 728108 | 728108 | 279 | -50 | 268 | 120 | NSR | ||||

| BBC7206 | Siga E | 728104 | 1347980 | 293 | -49 | 248 | 142 | 89.00 | 90.00 | 1.00 | 6.65 | HR |

| BBC7207 | Siga E | 728222 | 1348027 | 291 | -49 | 248 | 140 | 136.00 | 137.00 | 1.00 | 2.12 | HR |

| BBC7208 | Siga E | 728313 | 728313 | 283 | -49 | 248 | 100 | NSR | ||||

| BBC7209 | Siga E | 728311 | 1347894 | 283 | -50 | 250 | 60 | 13.00 | 14.00 | 1.00 | 1.49 | OX |

| BBC7220 | North Zone | 728639 | 1353346 | 276 | -50 | 312 | 100 | 23.00 | 28.00 | 5.00 | 0.38 | OX |

| and | 32.00 | 49.00 | 17.00 | 0.65 | OX | |||||||

| and | 75.00 | 78.00 | 3.00 | 0.55 | HR | |||||||

| BBC7221 | North Zone | 728548 | 1353361 | 273 | -50 | 132 | 130 | 75.00 | 76.00 | 1.00 | 3.05 | HR |

| and | 80.00 | 84.00 | 4.00 | 0.38 | HR | |||||||

| and | 95.00 | 98.00 | 3.00 | 0.49 | HR | |||||||

| and | 112.00 | 115.00 | 3.00 | 1.16 | HR | |||||||

| BBC7222 | Siga E | 728360 | 1347861 | 280 | -50 | 250 | 111 | 36.00 | 40.00 | 4.00 | 0.33 | OX |

| BBC7223 | Siga S | 728277 | 1345068 | 270 | -50 | 250 | 72 | 31.00 | 39.00 | 8.00 | 0.35 | OX |

| BBC7224 | Siga S | 728229 | 1345049 | 270 | -50 | 250 | 81 | 12.00 | 24.00 | 12.00 | 0.51 | OX |

| BBC7225 | Siga S | 728182 | 728182 | 269 | -50 | 249 | 80 | NSR | ||||

| BBC7226 | Siga S | 728340 | 728340 | 266 | -50 | 250 | 80 | NSR | ||||

| BBC7227 | Siga S | 728294 | 728294 | 266 | -50 | 250 | 80 | NSR | ||||

| BBC7228 | Siga S | 728247 | 728247 | 266 | -50 | 250 | 80 | NSR | ||||

| BBC7231 | P16 | 729521 | 1344797 | 261 | -50 | 270 | 72 | 19.00 | 31.00 | 12.00 | 1.06 | OX |

| Incl. | 27.00 | 31.00 | 4.00 | 1.86 | OX | |||||||

| and | 59.00 | 64.00 | 5.00 | 0.50 | HR | |||||||

| and | 69.00 | 72.00 | 3.00 | 0.68 | HR | |||||||

| BBC7232 | P16 | 729370 | 729370 | 261 | -50 | 268 | 76 | NSR | ||||

| BBC7233 | P16 | 729281 | 1344447 | 260 | -50 | 268 | 92 | 90.00 | 92.00 | 2.00 | 0.89 | HR |

| BBC7234 | P13 | 726320 | 726320 | 275 | -50 | 269 | 140 | NSR | ||||

| BBC7235 | P13 | 726403 | 726403 | 274 | -50 | 270 | 130 | NSR | ||||

| BBC7236 | P13 | 726350 | 726350 | 275 | -50 | 268 | 130 | NSR | ||||

| BBC7237 | P13 | 726352 | 726352 | 273 | -50 | 270 | 80 | NSR | ||||

| BBC7238 | P13 | 726163 | 726163 | 273 | -50 | 270 | 120 | NSR | ||||

| BBC7239 | P13 | 726145 | 1343997 | 271 | -50 | 270 | 100 | 96.00 | 97.00 | 1.00 | 2.44 | HR |

| BBC7240 | P13 | 726145 | 1343799 | 269 | -49 | 271 | 150 | 87.00 | 90.00 | 3.00 | 8.81 | HR |

| BBC7241 | P13 | 726132 | 726132 | 270 | -49 | 269 | 100 | NSR | ||||

| BBC7242 | P13 | 726127 | 1343749 | 268 | -50 | 267 | 100 | 59.00 | 60.00 | 1.00 | 2.26 | HR |

| BBC7243 | P13 | 725743 | 725743 | 273 | -50 | 114 | 90 | NSR | ||||

| BBC7244 | P13 | 726214 | 726214 | 269 | -50 | 268 | 120 | NSR | ||||

| BBC7245 | P13 | 726095 | 1342692 | 273 | -50 | 116 | 84 | 36.00 | 42.00 | 6.00 | 0.66 | OX |

| BBC7246 | P13 | 725896 | 725896 | 275 | -50 | 115 | 108 | NSR | ||||

| BBC7247 | P13 | 724776 | 1341625 | 272 | -50 | 117 | 114 | 21.00 | 25.00 | 4.00 | 0.70 | OX |

| BBC7248 | P13 | 724840 | 1341594 | 273 | -50 | 115 | 60 | 19.00 | 23.00 | 4.00 | 0.21 | OX |

| BBC7249 | P13 | 724739 | 1341505 | 271 | -50 | 115 | 120 | 24.00 | 37.00 | 13.00 | 0.41 | OX |

| and | 91.00 | 94.00 | 3.00 | 1.90 | HR | |||||||

| BBC7250 | P13 | 724787 | 1341481 | 271 | -50 | 113 | 60 | 31.00 | 38.00 | 7.00 | 1.10 | OX |

| Incl. | 31.00 | 33.00 | 2.00 | 3.16 | OX | |||||||

| BBC7251 | P13 | 724558 | 724558 | 273 | -50 | 114 | 80 | NSR | ||||

| BBC7252 | P13 | 724506 | 1340954 | 273 | -49 | 117 | 108 | 0.00 | 1.00 | 1.00 | 1.06 | OX |

| BBC7253 | P13 | 724605 | 724605 | 273 | -52 | 116 | 98 | NSR | ||||

| BBC7254 | Siga S | 727790 | 727790 | 266 | -50 | 249 | 80 | NSR | ||||

| BBC7255 | Siga S | 728280 | 728280 | 267 | -49 | 249 | 80 | NSR | ||||

| BBC7256 | P11 | 728053 | 728053 | 281 | -50 | 270 | 120 | NSR | ||||

| BBC7257 | P11 | 728043 | 728043 | 280 | -50 | 270 | 120 | NSR | ||||

| BBC7258 | P11 | 727638 | 1349521 | 288 | -50 | 270 | 120 | 67.00 | 70.00 | 3.00 | 1.22 | HR |

| BBD1350 | P16 | 729412 | 1344361 | 259 | -50 | 268 | 201 | 49.00 | 50.00 | 1.00 | 4.15 | OX |

| and | 126.00 | 128.85 | 3.00 | 0.84 | HR | |||||||

| and | 132.00 | 135.00 | 3.00 | 0.77 | HR | |||||||

| BBD1351 | P16 | 728970 | 728970 | 258 | -50 | 270 | 213 | NSR | ||||

| BBD1352 | P16 | 730374 | 730374 | 260 | -51 | 270 | 210 | NSR | ||||

| BBD1353 | P17 | 730410 | 1343174 | 261 | -55 | 270 | 390 | 294.80 | 296.40 | 1.60 | 2.98 | HR |

| and | 344.00 | 346.00 | 2.00 | 0.73 | HR | |||||||

| BBD1354 | Siga S | 728617 | 1345349 | 269 | -51 | 250 | 240 | 37.00 | 48.50 | 11.50 | 0.39 | OX |

| and | 115.00 | 116.00 | 1.00 | 18.77 | HR | |||||||

| and | 163.50 | 166.10 | 2.60 | 0.65 | HR | |||||||

| and | 194.00 | 207.00 | 13.00 | 0.53 | HR | |||||||

| BBD1355 | Siga E | 728706 | 1347108 | 273 | -52 | 249 | 174 | 22.00 | 37.00 | 15.00 | 0.94 | OX |

| Incl. | 22.00 | 28.00 | 6.00 | 1.68 | OX | |||||||

| and | 47.50 | 58.50 | 11.00 | 0.63 | OX | |||||||

| and | 76.50 | 78.50 | 2.00 | 1.37 | HR | |||||||

| and | 93.50 | 97.50 | 4.00 | 0.64 | HR | |||||||

| and | 113.50 | 116.50 | 3.00 | 0.60 | HR | |||||||

| and | 137.50 | 140.50 | 3.00 | 1.26 | HR | |||||||

| and | 145.50 | 157.50 | 12.00 | 0.57 | HR | |||||||

| BBD1356 | Siga E | 728599 | 1347236 | 274 | -50 | 250 | 297 | 112.00 | 116.00 | 4.00 | 0.90 | HR |

| and | 173.00 | 182.00 | 9.00 | 1.90 | HR | |||||||

| Incl. | 173.00 | 176.00 | 3.00 | 4.74 | HR | |||||||

| and | 199.00 | 200.00 | 1.00 | 1.65 | HR | |||||||

| and | 257.00 | 263.80 | 6.80 | 0.97 | HR | |||||||

| BBD1357 | North Zone | 729017 | 1353650 | 279 | -50 | 312 | 270 | 224.00 | 228.00 | 4.00 | 0.59 | HR |

| BBD1358 | North Zone | 728937 | 1353652 | 280 | -52 | 310 | 270 | 63.00 | 72.15 | 9.15 | 0.49 | OX |

| and | 126.00 | 127.60 | 1.60 | 6.09 | HR | |||||||

| and | 137.00 | 185.00 | 48.00 | 1.59 | HR | |||||||

| Incl. | 165.00 | 174.00 | 9.00 | 4.86 | HR | |||||||

| and | 234.00 | 259.36 | 15.36 | 0.63 | HR | |||||||

| Incl. | 234.00 | 237.00 | 3.00 | 1.35 | HR | |||||||

| BBD1359 | North Zone | 729094 | 1353643 | 276 | -54 | 312 | 381 | 65.00 | 66.00 | 1.00 | 5.37 | OX |

| BBD1360 | North Zone | 728275 | 1353337 | 270 | -50 | 312 | 258 | 11.00 | 14.00 | 3.00 | 0.26 | OX |

| and | 43.00 | 47.00 | 4.00 | 1.51 | OX | |||||||

| and | 120.00 | 124.00 | 4.00 | 0.81 | HR | |||||||

| and | 162.00 | 170.80 | 8.80 | 0.38 | HR | |||||||

| and | 199.00 | 206.30 | 7.30 | 0.60 | HR | |||||||

| BBD1361 | P17 S | 729160 | 729160 | 258 | -51 | 270 | 204 | NSR | ||||

| BBD1362 | P17 S | 730584 | 730584 | 266 | -51 | 270 | 135 | NSR | ||||

| BBD1363 | P17 S | 730488 | 730488 | 267 | -50 | 89 | 81 | NSR | ||||

| BBD1364 | Siga S | 728917 | 1344927 | 262 | -50 | 250 | 135 | 23.00 | 26.00 | 3.00 | 0.62 | OX |

| and | 34.00 | 36.00 | 2.00 | 0.99 | HR | |||||||

| and | 49.90 | 71.00 | 21.10 | 0.62 | HR | |||||||

| and | 75.00 | 80.00 | 5.00 | 1.22 | HR | |||||||

| BBD1365 | Siga S | 728635 | 1344983 | 266 | -53 | 252 | 192 | 36.00 | 42.65 | 6.65 | 0.72 | OX |

| and | 79.00 | 85.00 | 6.00 | 0.50 | HR | |||||||

| and | 104.00 | 105.85 | 1.85 | 2.90 | HR | |||||||

| BBD1366 | Siga S | 728608 | 1345400 | 270 | -50 | 249 | 251 | 42.00 | 45.00 | 3.00 | 1.41 | OX |

| and | 163.90 | 176.00 | 12.10 | 0.57 | HR | |||||||

| and | 191.00 | 195.00 | 4.00 | 0.57 | HR | |||||||

| and | 202.00 | 204.00 | 2.00 | 1.42 | HR | |||||||

| BBD1367 | P8P9 | 728505 | 1351717 | 272 | -52 | 310 | 465 | 81.00 | 82.00 | 1.00 | 4.25 | OX |

| and | 231.00 | 233.80 | 2.80 | 1.39 | HR | |||||||

| and | 313.00 | 320.40 | 7.40 | 2.67 | HR | |||||||

| and | 327.00 | 345.00 | 18.00 | 0.89 | HR | |||||||

| Incl. | 334.70 | 343.00 | 8.30 | 0.92 | HR | |||||||

| and | 424.00 | 449.00 | 25.00 | 0.68 | HR | |||||||

| Incl. | 428.80 | 443.00 | 14.00 | 0.84 | HR | |||||||

| BBD1368 | P8P9 | 727963 | 1351598 | 269 | -52 | 310 | 567 | 11.00 | 14.10 | 3.10 | 0.43 | OX |

| and | 74.00 | 78.00 | 4.00 | 1.11 | HR | |||||||

| and | 113.00 | 124.00 | 11.00 | 0.43 | HR | |||||||

| and | 141.00 | 147.50 | 6.50 | 1.47 | HR | |||||||

| and | 194.00 | 197.10 | 3.10 | 0.67 | HR | |||||||

| and | 275.00 | 283.00 | 8.00 | 0.53 | HR | |||||||

| and | 287.00 | 290.00 | 3.00 | 0.76 | HR | |||||||

| and | 308.00 | 330.00 | 22.00 | 0.69 | HR | |||||||

| Incl. | 310.00 | 317.00 | 7.00 | 0.97 | HR | |||||||

| and | 389.00 | 406.00 | 17.00 | 0.62 | HR | |||||||

| Incl. | 396.00 | 400.00 | 4.00 | 1.03 | HR | |||||||

| and | 414.00 | 424.00 | 10.00 | 0.62 | HR | |||||||

| and | 428.00 | 431.00 | 3.00 | 0.60 | HR | |||||||

| BBD1369 | P8P9 | 727935 | 1351556 | 269 | -51 | 315 | 496 | 11.00 | 12.00 | 1.00 | 1.67 | OX |

| and | 29.40 | 32.70 | 3.30 | 1.12 | HR | |||||||

| and | 83.50 | 84.50 | 1.00 | 3.55 | HR | |||||||

| and | 103.00 | 110.00 | 7.00 | 0.96 | HR | |||||||

| and | 119.00 | 122.00 | 3.00 | 1.35 | HR | |||||||

| and | 140.00 | 141.00 | 1.00 | 2.85 | HR | |||||||

| and | 193.00 | 198.00 | 5.00 | 1.94 | HR | |||||||

| and | 270.40 | 277.20 | 6.80 | 0.83 | HR | |||||||

| and | 285.00 | 293.75 | 8.75 | 1.48 | HR | |||||||

| Incl. | 291.00 | 293.75 | 3.00 | 3.65 | HR | |||||||

| and | 300.00 | 309.00 | 9.00 | 1.16 | HR | |||||||

| and | 315.00 | 318.00 | 3.00 | 0.61 | HR | |||||||

| and | 327.00 | 338.00 | 11.00 | 0.48 | HR | |||||||

| and | 378.00 | 383.00 | 5.00 | 0.76 | HR | |||||||

| BBD1370 | P8P9 | 727903 | 1351453 | 272 | -51 | 312 | 537 | 32.00 | 35.20 | 3.20 | 0.61 | HR |

| and | 95.00 | 96.00 | 1.00 | 3.64 | HR | |||||||

| and | 211.15 | 212.00 | 0.85 | 7.45 | HR | |||||||

| and | 238.00 | 283.00 | 45.00 | 1.09 | HR | |||||||

| Incl. | 271.00 | 279.00 | 8.00 | 2.56 | HR | |||||||

| and | 288.00 | 325.00 | 37.00 | 0.64 | HR | |||||||

| and | 352.00 | 357.85 | 5.85 | 0.89 | HR | |||||||

| and | 376.00 | 389.00 | 13.00 | 0.70 | HR | |||||||

| and | 395.00 | 403.00 | 8.00 | 0.58 | HR | |||||||

| BPC7210 | North Zone | 728928 | 1353759 | 281 | -50 | 313 | 437 | 1.00 | 20.00 | 19.00 | 0.52 | OX |

| and | 37.00 | 49.00 | 12.00 | 0.30 | OX | |||||||

| Incl. | 43.00 | 46.00 | 3.00 | 1.61 | OX | |||||||

| and | 161.00 | 184.00 | 23.00 | 0.78 | HR | |||||||

| Incl. | 168.00 | 174.40 | 6.00 | 1.82 | HR | |||||||

| and | 277.00 | 299.00 | 22.00 | 0.63 | HR | |||||||

| and | 354.00 | 360.00 | 6.00 | 1.57 | HR | |||||||

| BPC7211 | North Zone | 729368 | 1354172 | 283 | -51 | 310 | 349 | 37.00 | 49.00 | 12.00 | 0.30 | OX |

| and | 277.00 | 291.00 | 14.00 | 0.60 | HR | |||||||

| and | 295.00 | 299.00 | 4.00 | 1.22 | HR | |||||||

| and | 313.00 | 317.00 | 4.00 | 0.65 | HR | |||||||

| BPC7213 | North Zone | 729437 | 729437 | 286 | -50 | 312 | 105 | NSR | ||||

| BPC7214 | North Zone | 729485 | 1354333 | 290 | -50 | 311 | 263 | 52.00 | 55.00 | 3.00 | 1.51 | OX |

| and | 189.00 | 196.00 | 7.00 | 1.02 | HR | |||||||

| BPC7215 | North Zone | 728906 | 1353474 | 277 | -49 | 311 | 342 | 10.00 | 25.00 | 15.00 | 0.48 | OX |

| and | 208.00 | 210.00 | 2.00 | 3.07 | HR | |||||||

| BPC7216 | North Zone | 728927 | 1353525 | 278 | -50 | 311 | 343 | 18.00 | 25.00 | 7.00 | 0.50 | OX |

| and | 51.00 | 56.00 | 5.00 | 1.27 | OX | |||||||

| and | 69.00 | 73.00 | 4.00 | 0.55 | OX | |||||||

| and | 183.00 | 185.00 | 2.00 | 1.33 | HR | |||||||

| and | 189.00 | 203.00 | 14.00 | 2.01 | HR | |||||||

| Incl. | 197.00 | 203.00 | 6.00 | 3.03 | HR | |||||||

| and | 287.00 | 298.00 | 11.00 | 1.63 | HR | |||||||

| Incl. | 291.00 | 297.00 | 6.00 | 2.43 | HR | |||||||

| BPC7217 | North Zone | 728943 | 1353675 | 280 | -50 | 312 | 294 | 2.00 | 17.00 | 15.00 | 0.33 | OX |

| and | 21.00 | 32.00 | 11.00 | 0.48 | OX | |||||||

| and | 36.00 | 38.00 | 2.00 | 0.86 | OX | |||||||

| and | 42.00 | 46.00 | 4.00 | 0.60 | OX | |||||||

| and | 50.00 | 56.00 | 6.00 | 0.68 | OX | |||||||

| and | 135.00 | 149.00 | 14.00 | 0.58 | HR | |||||||

| and | 186.90 | 203.00 | 16.10 | 1.97 | HR | |||||||

| Incl. | 186.90 | 197.00 | 10.10 | 2.74 | HR | |||||||

| and | 207.00 | 215.00 | 8.00 | 0.65 | HR | |||||||

| and | 225.50 | 234.00 | 9.00 | 1.01 | HR | |||||||

| Incl. | 225.50 | 229.40 | 3.90 | 1.72 | HR | |||||||

| BPC7218 | North Zone | 728728 | 1353402 | 277 | -50 | 310 | 207 | 31.00 | 34.00 | 10.00 | 0.48 | OX |

| BPC7219 | North Zone | 728687 | 1353304 | 276 | -51 | 313 | 158 | 1.00 | 55.00 | 54.00 | 0.39 | OX |

* Mineralized intervals are reported as downhole lengths. True widths of mineralization are between 75-85% of drilled lengths.

Table 2 – Referenced Reported Historic Intervals

| Hole | Zone | Easting | Northing | Elv. | Dip | Azi. |

EOH (m) |

From (m) |

To (m) |

Length* (m) |

Grade (g/t Au) |

Type |

| BBD1220 | North Zone | 728901 | 1353648 | 279 | -56 | 312 | 229 | 150.00 | 170.00 | 21.00 | 5.35 | OX |

| BBC7141 | North Zone | 730390 | 1354301 | 278 | -45 | 315 | 100 | 27.00 | 41.00 | 14.00 | 2.22 | OX |

| BBD0483 | P8P9 | 727790 | 1351420 | 282 | -52 | 311 | 302 | 167.00 | 202.00 | 35.00 | 2.04 | HR |

| BBD0522 | P8P9 | 727819 | 1351528 | 281 | -51 | 309 | 351 | 207.00 | 252.00 | 45.00 | 1.95 | HR |

| BBD1124 | P17S | 730425 | 1343375 | 261 | -49 | 274 | 495 | 459.00 | 465.70 | 6.70 | 7.40 | HR |

| BBD1219 | North Zone | 728971 | 1353652 | 279 | -52 | 314 | 211 | 166.00 | 186.00 | 20.00 | 3.30 | HR |

| BBD1285 | North Zone | 728942 | 1353545 | 278 | -55 | 313 | 295 | 199.00 | 215.00 | 18.00 | 3.14 | HR |

| BBD1294 | P8P9 | 727740 | 1351448 | 280 | -58 | 313 | 257 | 99.00 | 140.50 | 40.40 | 1.72 | HR |

| BBD1312 | P8P9 | 727905 | 1351520 | 282 | -53 | 307 | 377 | 260.00 | 304.00 | 44.00 | 1.06 | HR |

| BBD1320 | North Zone | 729492 | 1354296 | 289 | -56 | 314 | 321 | 259.00 | 288.50 | 29.50 | 1.14 | HR |

| BBD1324 | North Zone | 728995 | 1353667 | 280 | -52 | 312 | 312 | 193.00 | 216.00 | 23.00 | 2.55 | HR |

| BBD1334 | P17S | 730483 | 1343350 | 261 | -54 | 273 | 519 | 488.50 | 498.50 | 10.00 | 1.12 | HR |

| BBD1348 | P16 | 729566 | 1344413 | 259 | -50 | 273 | 303 | 214.00 | 228.35 | 14.35 | 0.92 | HR |

________________________

1. Please see Table 1 for estimated true widths.

2. Composite includes below cut-off dilution.

3. The drill results were previously disclosed in the Company’s press releases dated June 10, 2025 and January 26, 2025. See also Table 2.

4. Refer to the Company’s prospectus dated and lodged with ASIC on July 11, 2025 (the “ASX Prospectus”), a copy of which is available on the Company’s website for the Company’s Mineral Resource Estimate: 27,530kt at 0.78g/t Au for 692koz Au Measured Mineral Resources, 151,735kt at 0.78g/t Au for 3,814koz Au Indicated Mineral Resources and 20,015kt at 0.95g/t Au for 610koz Inferred Mineral Resources. The Company confirms it is not aware of any new information or data that materially affects the information included in the Prospectus and that all material assumptions and technical parameters underpinning the mineral resources in the Prospectus continue to apply and have not materially changed.

5. This statement of the Company’s goal of increasing the current stated 5 million global resource base to a targeted 7 to 10 million ounces longer term is an aspirational statement, and the Company does not yet have reasonable grounds to believe the statement can be achieved.

6. Refer to the ASX Prospectus. The Company confirms it is not aware of any new information or data that materially affects the information included in the ASX Prospectus and that all material assumptions and technical parameters underpinning the forecasted gold production targets in the Prospectus continue to apply and have not materially changed.

7. The drill results were previously disclosed in the Company’s press releases dated December, 21, 2022; March 6, 2023; December 21, 2022; and January 26, 2025, respectively. See also Table 2.

8. Composite includes below cut-off dilution.

9. The drill results were previously disclosed in the Company’s press release dated March 6, 2023. See also Table 2.

10. Refer to footnote 6.

11. Refer to footnote 6.

About Orezone Gold Corporation

Orezone Gold Corporation (TSX: ORE, ASX: ORE, OTCQX: ORZCF) is a West African gold producer engaged in mining, developing, and exploring its 90%-owned flagship Bomboré Gold Mine in Burkina Faso. Construction of the stage 1 hard rock expansion is well underway, with first gold expected in Q4-2025. Combined production from the oxide and stage 1 hard rock operations is forecasted to total between 170,000 and 185,000 ounces in 2026.10 The Company is also advancing the stage 2 hard rock expansion, which is forecasted to increase annual production to between 220,000 and 250,000 ounces.11

The technical report entitled Bomboré Phase II Expansion, Definitive Feasibility Study is available on SEDAR+ and the Company’s website.

Contact Information

Patrick Downey

President and Chief Executive Officer

Kevin MacKenzie

Vice President, Corporate Development and Investor Relations

Tel: 1 778 945 8977

info@orezone.com / www.orezone.com

For further information please contact Orezone at +1 (778) 945 8977 or visit the Company’s website at www.orezone.com.

This announcement is authorised for ASX release by Patrick Downey, President, CEO and Director.

The Toronto Stock Exchange neither approves nor disapproves the information contained in this news release.

Qualified Person and Competent Persons Statement

Alastair Gallaugher (CGeol), Exploration Manager for Orezone, is the Qualified Person under NI 43-101 and has reviewed and approved the scientific and technical information contained in this news release.

Information in this press release that relates to exploration results is based on, and fairly represents, information and supporting documentation prepared by Mr. Gallaugher, a Competent Person who is a Member of the Geological Society of London. Mr. Gallaugher has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity which he is undertaking to qualify as a ‘Competent Person’ as defined in the 2012 Edition of the ‘Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves’ (JORC Code). Mr. Gallaugher is an employee of the Company and consents to the inclusion in this announcement of all technical statements based on his information in the form and context in which it appears.

QA/QC

The mineralized intervals are based on a lower cut-off grade of 0.28g/t in the Oxide+Upper Transition zone, and 0.45g/t Au in the Lower Transition+Hard Rock zone. The half-core drilling samples were cut using a diamond saw by Orezone employees. The samples were prepared by BIGS Global Burkina s.a.r.l. (“BIGS Global”) and then split by Orezone to 1 kg using Rotary Sample Dividers (“RSDs”). A 1kg aliquot was analyzed for leachable gold at BIGS Global in Ouagadougou, by bottle-roll cyanidation using a LeachWellTM catalyst. The leach residues from all samples with a leach grade greater than or equal to 0.25g/t Au were prepared by BIGS Global and then split by Orezone to 50g using RSDs. A 50g aliquot was analyzed by fire assay at BIGS Global.

Orezone employs a rigorous Quality Control Program including a minimum of 10% standards, blanks and duplicates. The composite width and grade include the final leach residue assay results for most of the drill intercepts reported.

Cautionary Note Regarding Forward-Looking Statements

This press release contains certain information that constitutes “forward-looking information” within the meaning of applicable Canadian Securities laws and “forward-looking statements” within the meaning of applicable U.S. securities laws (together, “forward-looking statements”). Forward-looking statements are frequently characterized by words such as “plan”, “expect”, “project”, “intend”, “believe”, “anticipate”, “estimate”, “potential”, “possible” and other similar words, or statements that certain events or conditions “may”, “will”, “could”, or “should” occur.

Forward-looking statements in this press release include, but are not limited to statements with respect to the exploration program and the significant exploration upside at Bomboré including that the broader system remains open at depth, along strike and outside of the currently delineated mineralized trends; the potential to materially expand the project’s resource base from the current global 5 million gold ounces, to a targeted 7 to 10 million gold ounces longer term (as an aspirational statement, being a forward-looking statement for Canadian and U.S. securities laws and not a forward-looking statement for Australian purposes) and the ongoing production expansion to 220,000 to 250,000 ounces per annum; evidence that the hanging wall and footwall of the broader 14km long reserve defined system are prospective for additional near-surface discoveries; the initial step-out results support the interpretation that P16 is a sub-parallel trend to the P17 Trend, which significantly expands the exploration model and potential within this region of the project; and significant potential remains to extend resources to the north of the existing open pit designs in the North Zone.

Forward-looking statements are not guarantees of future performance and involve known and unknown risks, uncertainties, assumptions and other important factors, many of which are beyond the control of the Company, its Directors, and management, and which could cause actual results or events to differ materially from those expressed or implied. Past performance is not a guide to future performance. Such risks and uncertainties include, but are not limited to, terrorist or other violent attacks, the failure of parties to contracts to honour commitments, unexpected changes in laws, rules or regulations or their enforcement, social or labour unrest, changes in commodity prices, failure or inadequacy of infrastructure, project cost overruns or unanticipated costs and expenses, accidents and equipment breakdowns, political risk, unanticipated changes in key management personnel, the spread of diseases, epidemics and pandemics, adverse market or business conditions, failure of exploration or drilling programs to deliver anticipated results, uncertainties relating to the availability and costs of future financing, and other factors described in the Company’s most recent audited annual consolidated financial statements, annual MD&A, Annual Information Form for the year ended December 31, 2024, and in Section 4 of the Company’s prospectus dated July 11, 2025, copies of which are available on SEDAR+ (www.sedarplus.ca) and the Company’s website. Readers are cautioned not to place undue reliance on forward-looking statements.

Forward-looking statements are based on the applicable assumptions and factors management considers reasonable as of the date hereof, based on the information available to management at such time. These assumptions and factors include, but are not limited to, assumptions and factors related to the Company’s ability to carry on current and future operations, including: development and exploration activities; the timing, extent, duration and economic viability of such operations, including any mineral resources or reserves identified thereby; the accuracy and reliability of estimates, projections, forecasts, studies and assessments; the Company’s ability to meet or achieve estimates, projections and forecasts; the availability and cost of inputs; the price and market for outputs, including gold; foreign exchange rates; taxation levels; the timely receipt of necessary approvals or permits; the ability to meet current and future obligations; the ability to obtain timely financing on reasonable terms when required; the current and future social, economic and political conditions; and other assumptions and factors generally associated with the mining industry.

Although the forward-looking statements contained in this press release are based upon what management of the Company believes are reasonable assumptions, the Company cannot assure investors that actual results will be consistent with these forward-looking statements. These forward-looking statements are made as of the date of this press release and are expressly qualified in their entirety by this cautionary statement. Subject to applicable securities laws, the Company does not assume any obligation to update or revise the forward-looking statements contained herein to reflect events or circumstances occurring after the date of this press release.

Table 1 – JORC Code, 2012 Edition

Section 1 – Sampling Techniques and Data

| Criteria | JORC Code Explanation | Commentary |

| Sampling techniques |

|

|

| Drilling techniques |

|

|

| Drill sample recovery |

|

|

| Logging |

|

|

| Sub-sampling techniques and sample preparation |

|

|

| Quality of assay data and laboratory tests |

|

|

| Verification of sampling and assaying |

|

|

| Location of data points |

|

|

| Data spacing and distribution |

|

|

| Orientation of data in relation to geological structure |

|

|

| Sample security |

|

|

| Audits or reviews |

|

|

Section 2 – Reporting of Exploration Results

| Criteria | JORC Code Explanation | Commentary |

| Mineral tenement and land tenure status |

|

|

| Exploration done by other parties |

|

|

| Geology |

|

|

| Drill hole Information |

|

|

| Data aggregation methods |

|

|

| Relationship between mineralisation widths and intercept lengths |

|

|

| Diagrams |

|

|

| Balanced reporting |

|

|

| Other substantive exploration data |

|

|

| Further work |

|

|

Photos accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/c5d5de1e-0fae-4d5a-a0d9-229414b80511

https://www.globenewswire.com/NewsRoom/AttachmentNg/b5769060-056a-4d7e-bbcd-64ebeb1c69f1

https://www.globenewswire.com/NewsRoom/AttachmentNg/109bac49-5f17-4f44-9c5f-05b8d5502265

https://www.globenewswire.com/NewsRoom/AttachmentNg/ed50789e-bef0-4fe9-811b-3543a437a31f

Figure 1

Bomboré Plan Map Highlighting Selected Intercepts

Figure 2

North Hill Zone Composite Long Section Highlighting Selected Intercepts (Looking Southeast)

Figure 3

P8P9 Zone Composite Long Section Highlighting Selected Intercepts (Looking Southeast)

Figure 4

P8P9 Zone Composite Cross Section Highlighting Selected Zone (Looking Northwest)

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.